ASME and API Codes and Standards, Driving Excellence in Engineering

In the vast landscape of engineering, particularly in the mechanical, chemical discipline and petroleum engineering, compliance to codes and standards is vital. Among the available guidelines, two organizations stand out for their contributions to ensuring safety, reliability, and efficiency in engineering practices: the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API). Let’s see their significance, scope, and impact on various industries.

ASME: Setting the Standard for Mechanical Engineering

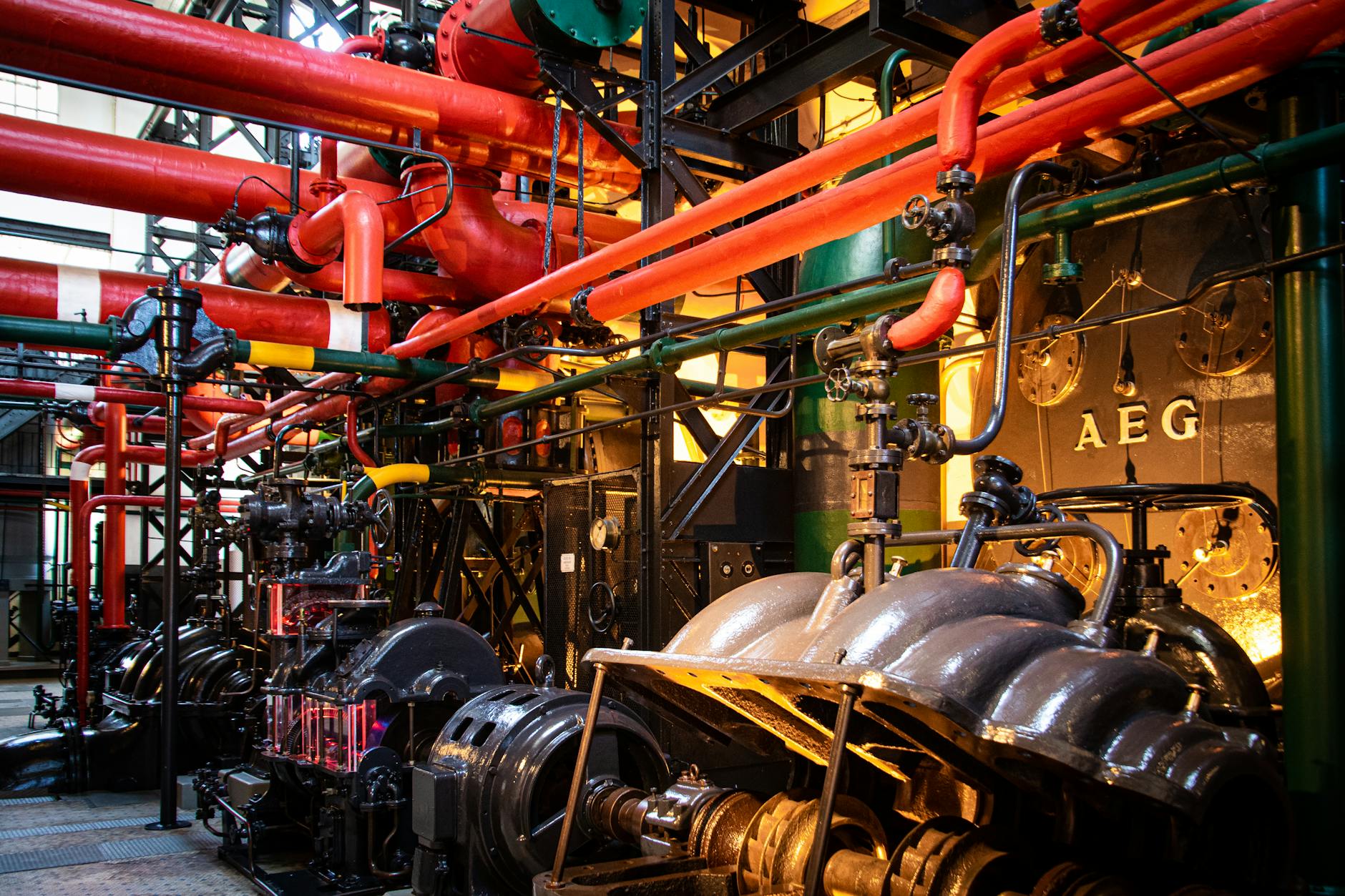

The American Society of Mechanical Engineers (ASME) has been a cornerstone of engineering standards since its inception in 1880. ASME codes and standards cover a broad range of disciplines, including pressure vessels, piping systems, boilers, and nuclear components, among others. Among its most renowned codes are those under the B31 series, which deal with piping systems.

ASME B31 Series: This series include multiple codes tailored to different types of piping systems. For instance, ASME B31.1 focuses on power piping, ASME B31.3 addresses process piping, and ASME B31.4 and B31.8 deal with pipeline transportation systems for liquids, gases, and slurries. These codes provide guidelines for design, fabrication, installation, inspection, testing, and maintenance of piping systems, ensuring they meet rigorous safety and performance standards.

API: Shaping the Petroleum Industry

The American Petroleum Institute (API) is another prominent standards organization, particularly influential in the oil and gas industry. Founded in 1919, API develops and maintains standards for equipment, systems, and processes involved in petroleum production, refining, transportation, and distribution.

API 510, 570, and 653: These API codes focus on the inspection, repair, alteration, and rerating of pressure vessels, piping systems, and storage tanks in refining, petrochemical, and chemical plants. API 510 covers pressure vessel inspection, API 570 addresses piping inspection, and API 653 deals with the inspection of aboveground storage tanks.

API 5L and API 6A: These standards are vital in the realm of pipeline and wellhead equipment. API 5L specifies the requirements for the manufacture of seamless and welded steel line pipes used for conveying gas, water, and oil in the petroleum and natural gas industries. API 6A, on the other hand, focuses on the specification for wellhead and Christmas tree equipment.

Significance and Impact

Both ASME and API codes and standards play important roles in ensuring the integrity, reliability, and safety of engineering systems across various industries. Compliance with these standards is not just a matter of regulatory requirement but also a commitment to excellence and best practices in engineering.

Adherence to ASME and API standards offers numerous benefits:

- Safety Assurance: By adhering to stringent design, fabrication, and inspection guidelines, the risk of accidents, leaks, and failures is minimized, enhancing overall safety in industrial operations.

- Reliability and Efficiency: Engineering systems designed and constructed in accordance with established standards are more reliable, leading to reduced downtime, increased operational efficiency, and enhanced productivity.

- Regulatory Compliance: Many regulatory bodies mandate compliance with recognized standards such as those developed by ASME and API. Adhering to these standards ensures regulatory compliance, minimizing legal risks and liabilities.

- Global Acceptance: ASME and API standards enjoy widespread acceptance globally, facilitating interoperability and trade across international borders.

- Innovation and Advancement: These standards serve as foundations for innovation and technological advancement in engineering practices, driving continuous improvement and evolution in the industry.

ASME and API codes and standards serve as guiding beacons for engineers, ensuring the highest levels of safety, reliability, and efficiency in engineering practices. Their contributions to various industries are invaluable, shaping the landscape of engineering excellence and fostering sustainable development worldwide. Adhering to these standards is not just a professional obligation but a testament to a commitment to quality, integrity, and excellence in engineering endeavours.